Creating a total different tea bag

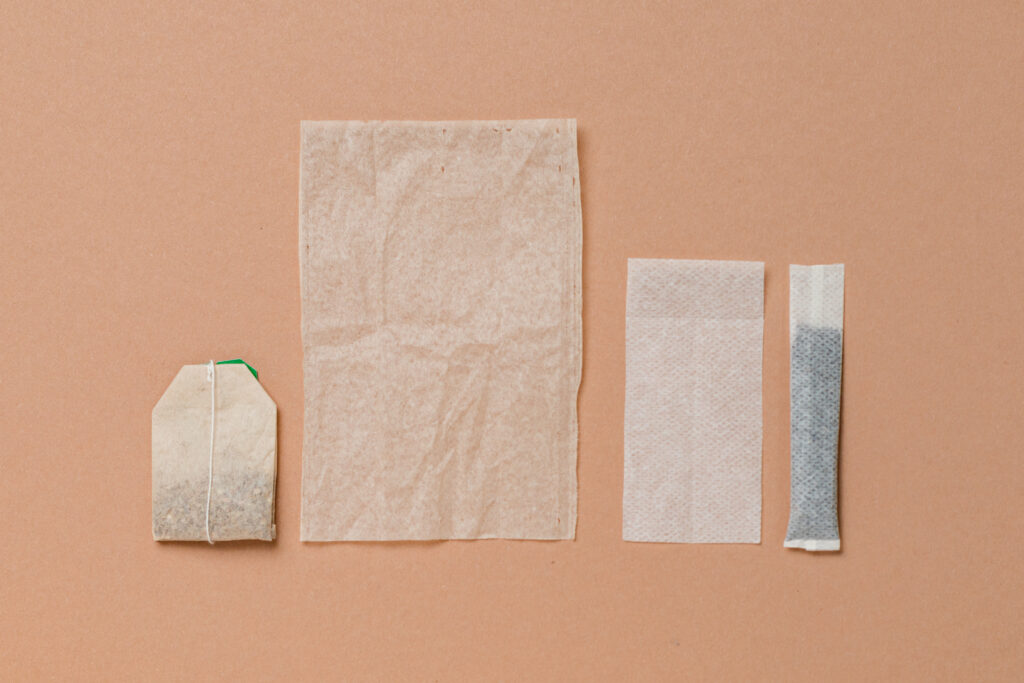

The design of the Steaper does not contain the usual string and label, so the tea bag had to be able to be connected directly to the Strip. The first prototype made was made of foil with slots with filter paper, didn’t really worked out. so the only thing left was to creating a total different tea bag.

Another material had to be found for the tea bag (pouch), which was actually already available, namely filter paper and/or polymer variants. To investigate it further, various brands of tea were examined and the construction of the tea bag was examined in particular. The whole provided insight into the production method, actions, materials used, production capacities, filling methods and types of fillings.

Machine manufacturers were visited, the machines used by the industry were viewed and further research was done.

It soon became clear that none of the tea bag filling machines on the market were suitable or could be adapted. Another factor was that no deviations from the design/model of the Pouch were allowed and no modifications were made to it. Furthermore, production capacity and price were part of the decision not to continue with the machines used in the tea industry in this project.

In another sector (pharmaceutical and food industry) a completely different type of machine was found that, with a few minor adjustments, was completely sufficient to produce the Pouch.

In short, the tea bag was for the most part ready with the following advantages;

- More than 60% less material than the conventional tea bag

- High volume production, from 150 up to 850 per minute

- Vertical position in the liquid, better flow

- Length and width adaptable of the tea bag (pouch)

- Variable in filling weight

- The Start, The Strip, The Indicator, Photo album, Legal documents, For sale and contact

“Use less, save more”